Meta has unveiled the next iteration of its sensor-packed research eyewear, the Aria Gen 2. This latest model follows the initial version introduced in 2020. The original glasses came equipped with a variety of sensors but lacked a display, and were not designed as either a prototype or a consumer product. Instead, they were exclusively meant for research to explore the types of data that future augmented reality (AR) glasses would need to gather from their surroundings to provide valuable functionality.

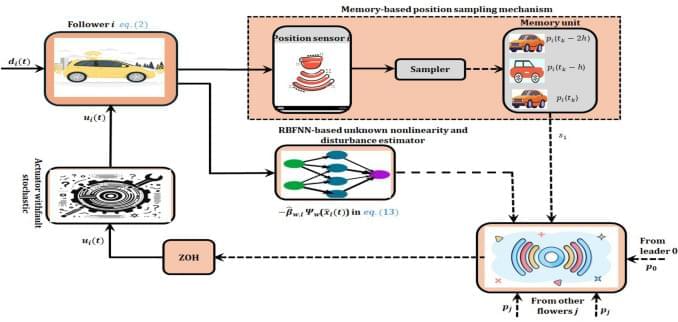

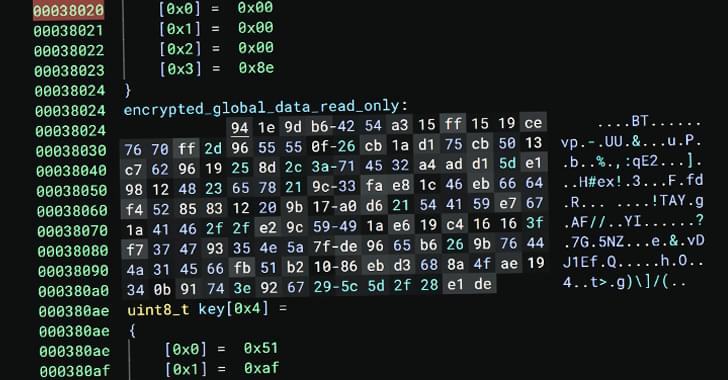

In their Project Aria initiative, Meta explored collecting egocentric data—information from the viewpoint of the user—to help train artificial intelligence systems. These systems could eventually comprehend the user’s environment and offer contextually appropriate support in daily activities. Notably, like its predecessor, the newly announced Aria Gen 2 does not feature a display.

Meta has highlighted several advancements in Aria Gen 2 compared to the first generation: