Year 2024 face_with_colon_three

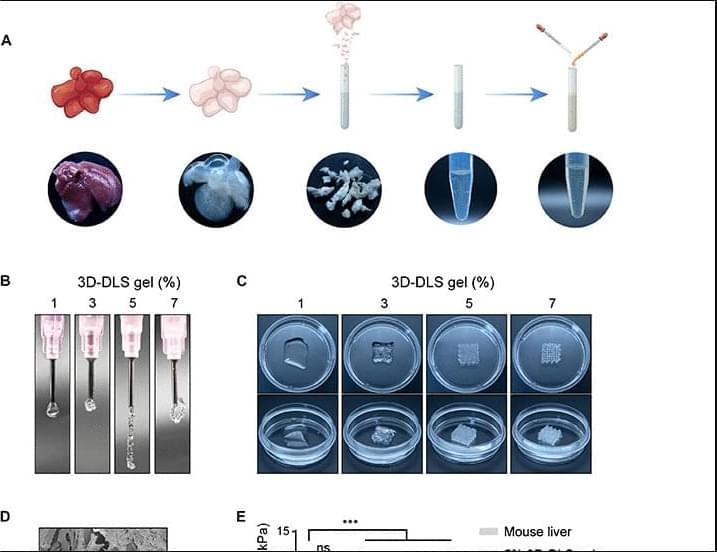

3D-bioprinting livers based on expandable primary hepatocytes and liver-specific bioink could save mouse liver failure.

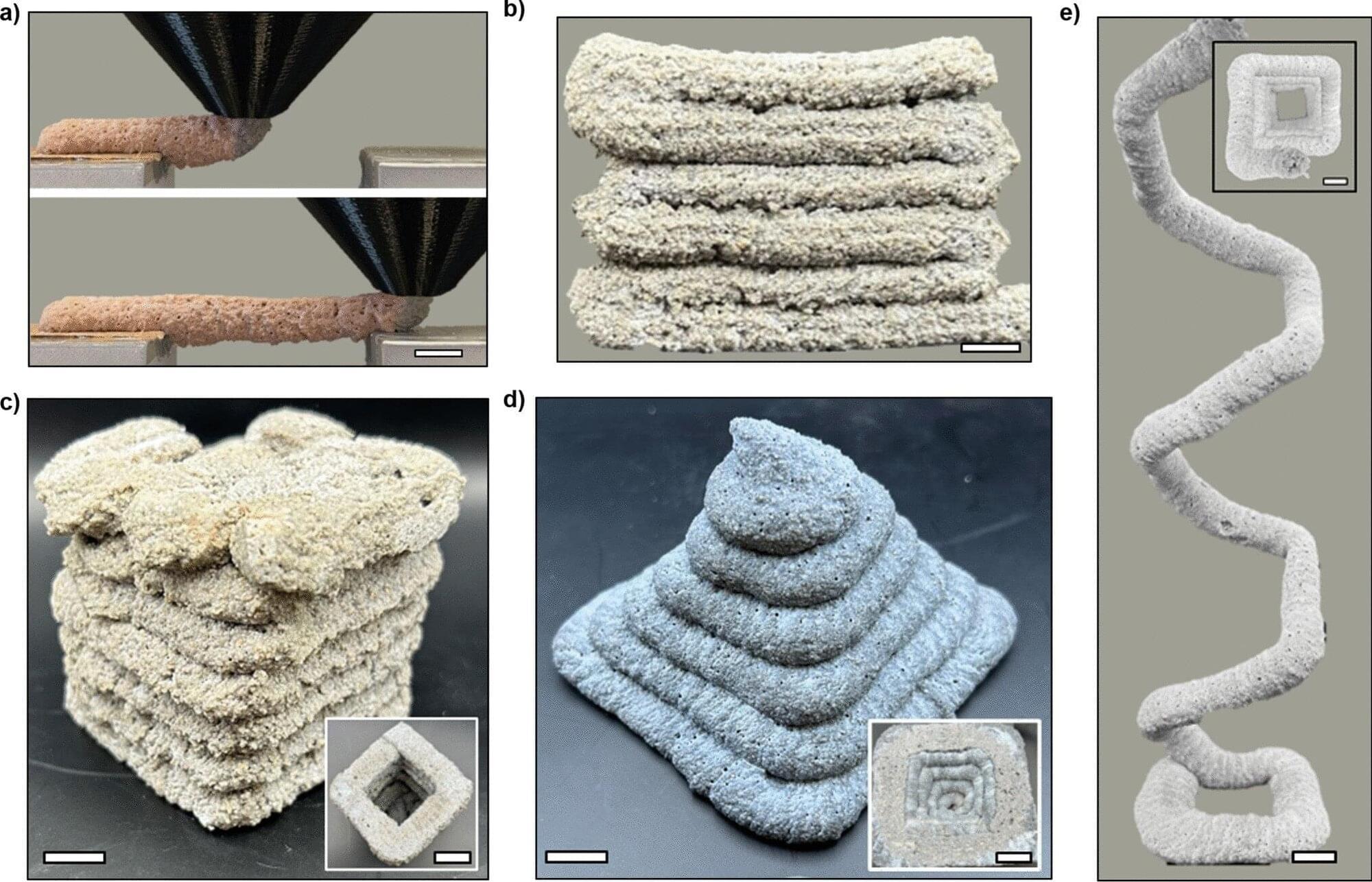

Researchers at Oregon State University have developed a quick-setting, environmentally friendly alternative to concrete they hope can one day be used to rapidly 3D print homes and infrastructure.

Also known as additive manufacturing, 3D printing is already being used to help solve construction challenges such as the global housing crisis that’s emerged as Earth’s population approaches 8.5 billion.

But cement, the binding agent in concrete, accounts for about 8% of the planet’s carbon dioxide emissions, and concrete’s curing time—which can be multiple days—and required structural supports can inhibit progress on construction projects.

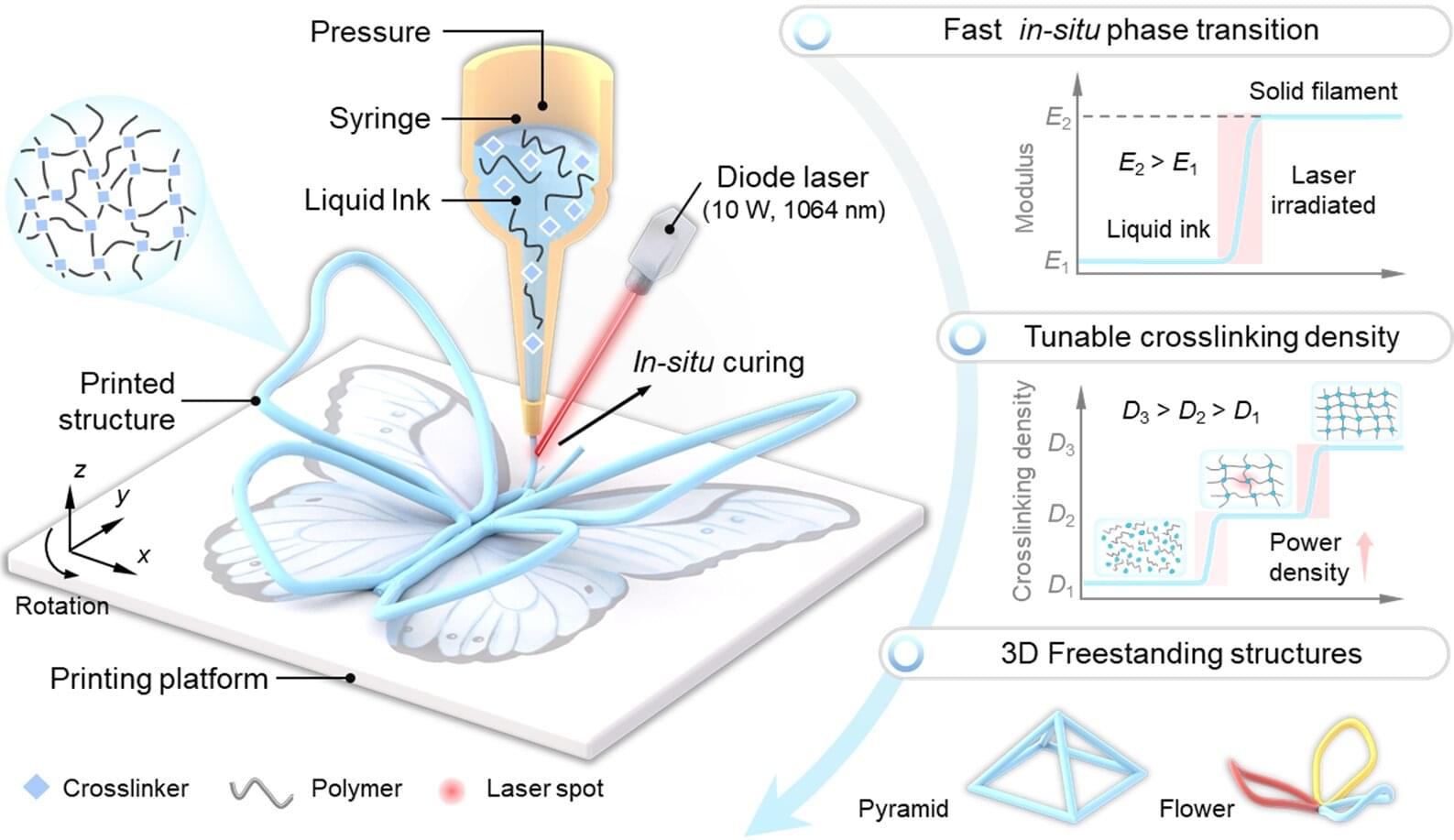

Thermosets, such as epoxy and silicon rubbers, are a class of polymer (i.e., plastic) materials that harden permanently when they undergo a specific chemical reaction, known as “crosslinking.” These materials are highly durable, heat-resistant with excellent electrical insulation in various applications such as in adhesives, coatings, and automotive parts.

Thermosets are also widely used to fabricate electronic components, including switches, circuit breakers and other core circuit components.

So far, thermoset-based free-standing devices have proved difficult to construct by using conventional 3D printing processes. One key reason for this is that the materials need to be provisionally supported by other supporting objects until they become solid, which adds more steps to the printing process.

3Doodler, known for its 3D-printing pens, has announced a kid-friendly version of its Chef 3D pen that prints with candy instead of plastic filament. The new 3Doodler Candy, arriving later this year, swaps a power cord for a 45-minute rechargeable battery and uses gluten-free vegan isomalt capsules instead of sugar.

The candy comes out of the pen at 45 degrees Fahrenheit, so it’s safe for kids aged six and up to use.

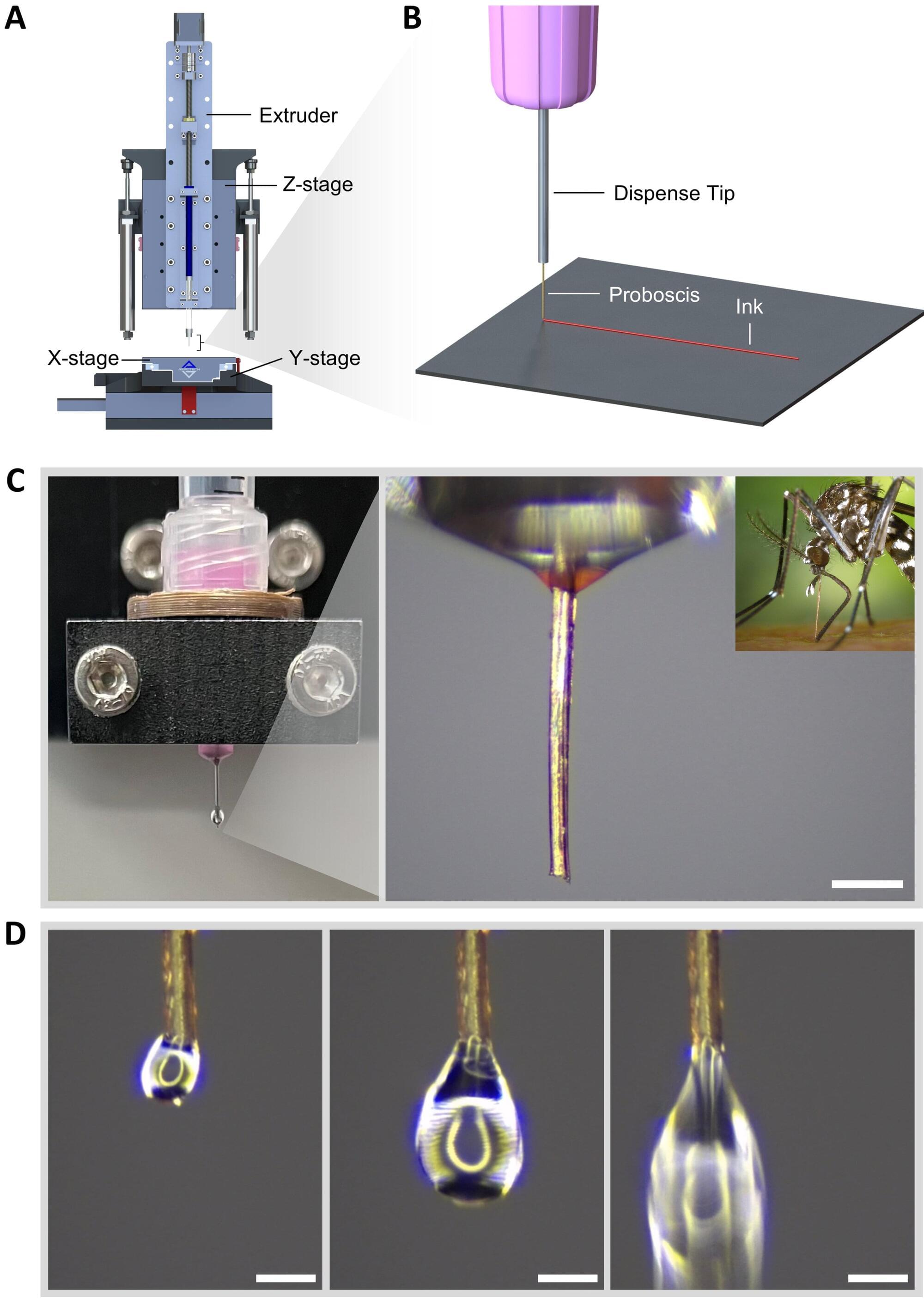

When it comes to innovation, engineers have long proved to be brilliant copycats, drawing inspiration directly from nature. But now some scientists are moving beyond simple imitation to incorporating natural materials into their designs. Stuck for ideas on how to create ultra-fine, low-cost 3D printing nozzles, researchers at McGill University in Canada repurposed the proboscis of a deceased female mosquito to create a sustainable, high-resolution 3D printing tip.

The work is published in the journal Science Advances.

High-resolution 3D printing is a process that creates three-dimensional objects with extremely fine details and very smooth surfaces. The technology is used in numerous fields such as aerospace, dentistry and biomedical research. However, its level of precision comes at a steep cost. The tiny nozzles can cost more than $80 per tip and are made of metal or plastic, both of which are nonbiodegradable.

Additive manufacturing, or 3D printing, is normally a one-way street. In a digital light processing (DLP) printer, a structured pattern is projected onto a layer of liquid resin, which cures and solidifies. This builds an object up, layer-by-layer. But if the print isn’t exactly right, there’s no easy way to fix it after the fact: it usually ends up in the trash.

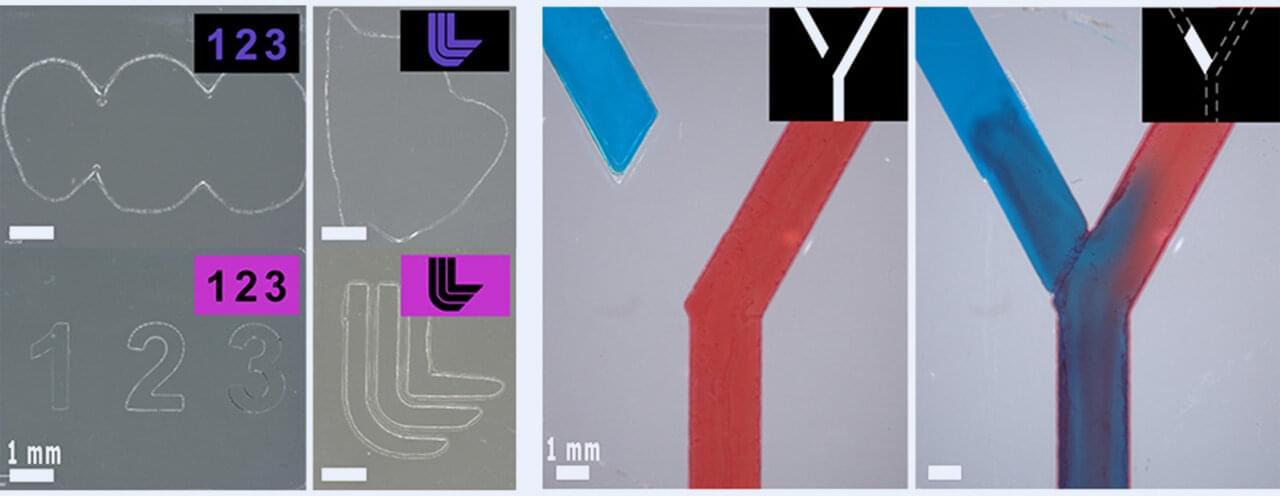

In a new study, published in Advanced Materials Technologies, researchers at Lawrence Livermore National Laboratory (LLNL) developed a hybrid additive and subtractive manufacturing system with a unique resin that enhances traditional 3D printing by introducing dual-wavelength behavior. Under blue light, the resin cures and hardens. Under ultraviolet light, it degrades back into a liquid. The hybrid printing system enables corrective manufacturing, provides improved print resolution and allows for upcycling and recycling of parts.

“Imagine if a company needed a part to fit a certain machine but it’s a prototype and they’re not quite sure what they want,” said LLNL scientist and author Benjamin Alameda. “They could theoretically print with our resin. And if there were defects or something they wanted to change about it, they don’t have to print a whole new part. They could just shine another wavelength on it and modify the existing part. That’s useful and less wasteful.”

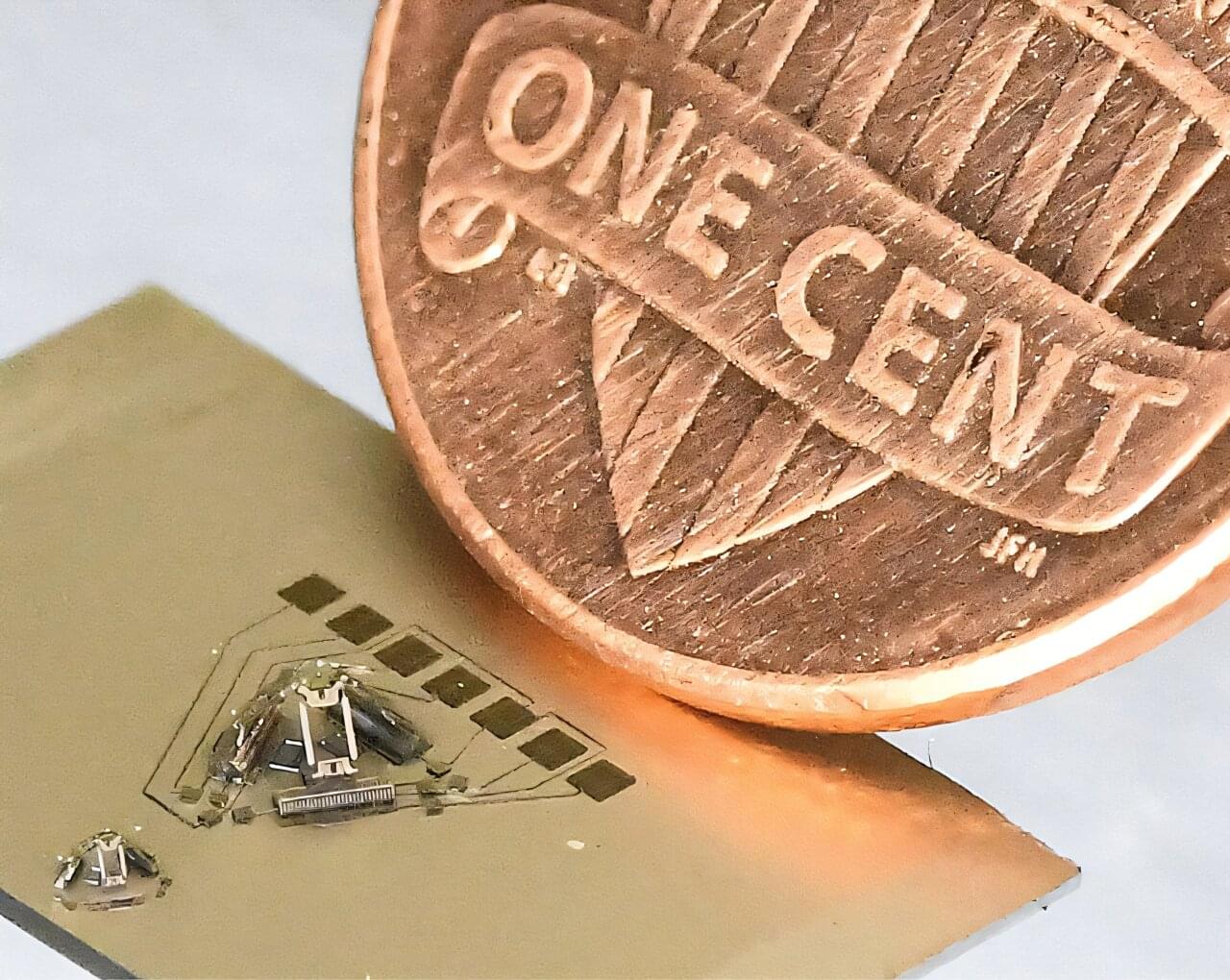

In the 1980s when micro-electro-mechanical systems (MEMS) were first created, computer engineers were excited by the idea that these new devices that combine electrical and mechanical components at the microscale could be used to build miniature robots.

The idea of shrinking robotic mechanisms to such tiny sizes was particularly exciting given the potential to achieve exceptional performance in metrics such as speed and precision by leveraging a robot’s smaller size and mass. But making robots at smaller scales is easier said than done due to limitations in microscale 3D manufacturing.

Nearly 50 years later, Ph.D. students Steven Man and Sukjun Kim, working with Mechanical Engineering Professor Sarah Bergbreiter, have developed a 3D printing process to build tiny Delta robots called microDeltas. Delta robots at larger scales (typically two to four feet in height) are used for picking, placing, and sorting tasks in manufacturing, packaging, and electronics assembly. The much smaller microDeltas have the potential for real-world applications in micromanipulation, micro assembly, minimally invasive surgeries, and wearable haptic devices.

Concrete 3D printing reduces both time and cost by eliminating traditional formwork, the temporary mold for casting. Yet most of today’s systems rely on extrusion-based methods, which deposit material very close to a nozzle layer by layer. This makes it impossible to print around reinforcement bars (rebars) without risk of collision, limiting both design flexibility and structural integrity of builds.

Kenji Shimada and researchers in his Carnegie Mellon University’s Computational Engineering and Robotics Laboratory (CERLAB), are breaking through that limitation with a new simulation tool for spray-based concrete 3D printing.

“Spray-based concrete 3D printing is a new process with complicated physical phenomena,” said Shimada, a professor of mechanical engineering. “In this method, a modified shotcrete mixture is sprayed from a nozzle to build up on a surface, even around rebar.”

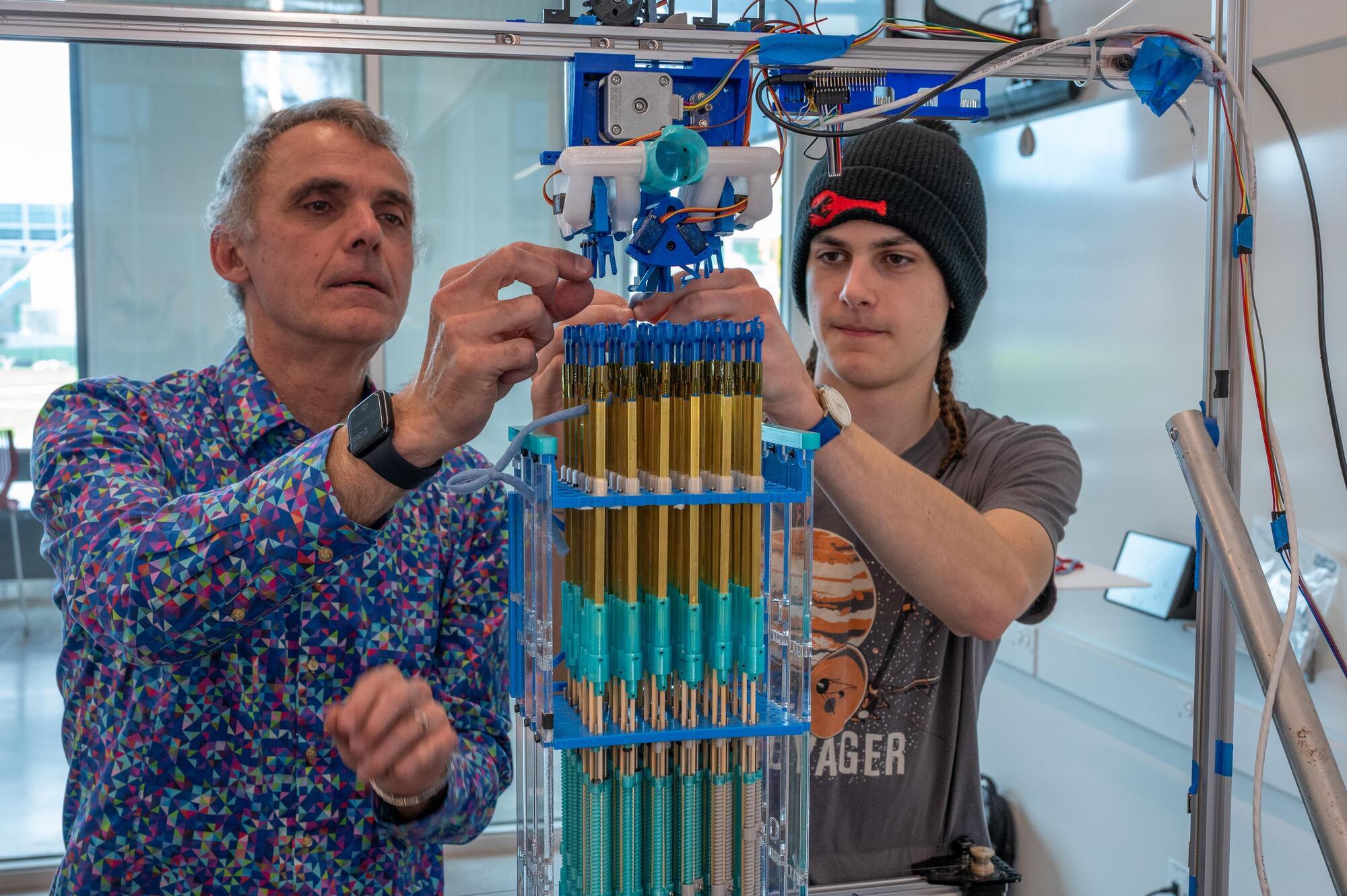

If you find 3D printers to be just a little too coldly futuristic, this contraption might be more to your liking. Scientists from Cornell University have created a machine that knits solid 3D objects out of nice old-timey conventional yarn.

The prototype device is made mainly of 3D-printed components, and incorporates a bed of knitting needles arranged in a 6 × 6 block. A motorized knitting head dispenses yarn to any of those needles in sequence, as determined by a program on a computer that’s controlling it.

Each of the needles in turn consists of a 3D-printed symmetrical double hook connected to a brass support tube. Because the front and rear sections of the hook move independently, it’s possible for the device to either knit or purl, depending on which section of the hook picks up the first loop of yarn.

The study notes in its conclusions, “We have presented G-FLight printing as an effective tool for the rapid gravity-independent fabrication of aligned tissues, focusing on muscle tissue as an application.”

Can muscle tissue be 3D-printed in outer space to improve astronaut health? This is what a recent study published in Advanced Science hopes to address as a team of scientists investigated how human tissue can be manufactured in space. This study has the potential to help scientists, researchers, and the public better understand new methods for not only aiding in long-term space travel but also combating diseases on Earth.

For the study, the researchers used a series of parabolic flights to test G-FLight (Gravity-independent Filamented Light), which is a novel 3D printing biomanufacturing system capable of producing muscle cells and fibers in a matter of seconds. The purpose of the parabolic flights was to simulate microgravity, which is produced by the airplane sharply diving after gradually rising in altitude. The goal of the study was to ascertain if G-Flight could successfully 3D-print muscle fibers under microgravity conditions. In the end, the researchers found that G-FLight successfully produced muscle fibers under microgravity conditions during parabolic flights.