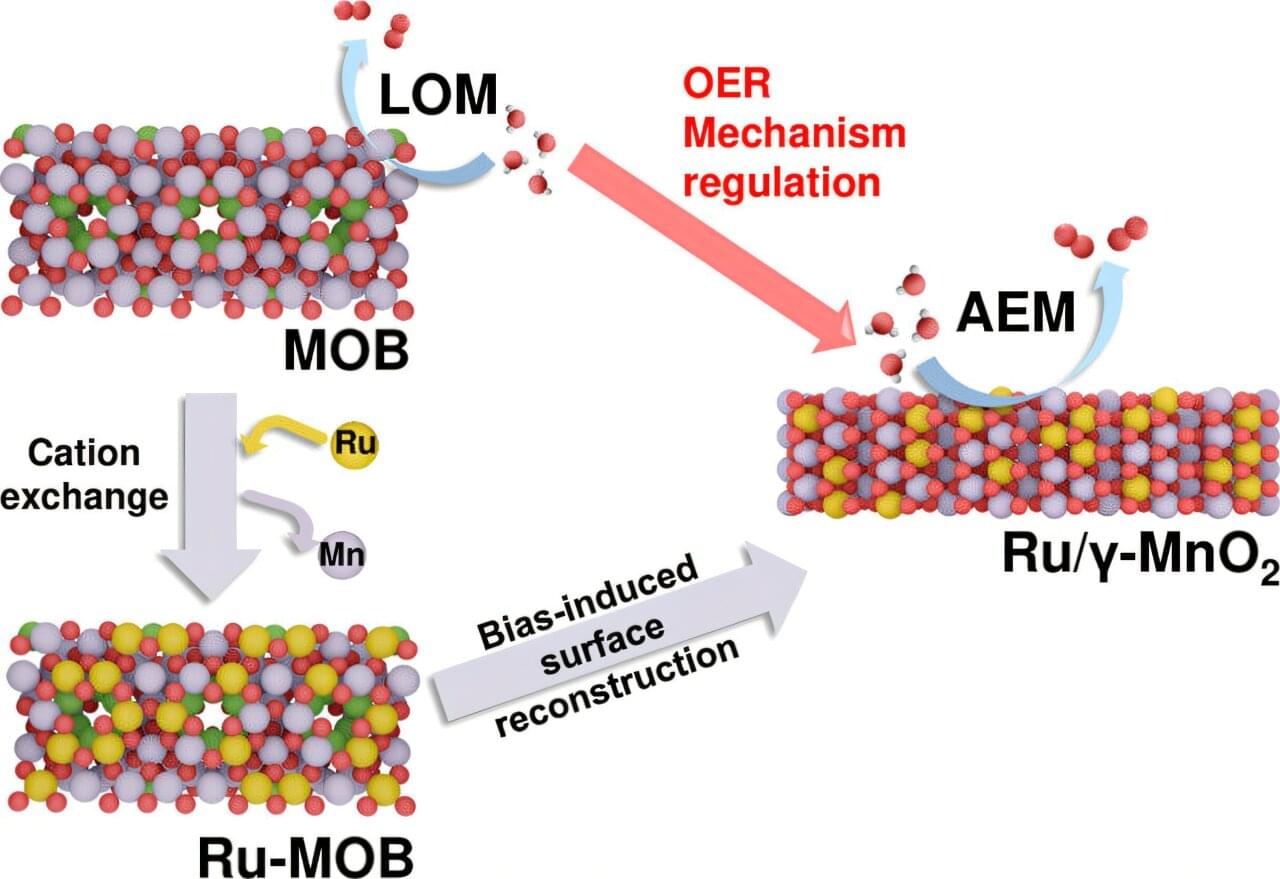

An international research team led by Professor Philip C.Y. Chow at The University of Hong Kong (HKU) has unveiled a new catalyst that overcomes a major challenge in producing green hydrogen at scale. This innovation makes the process of producing oxygen efficiently and reliably in the harsh acidic environment used by today’s most promising industrial electrolyzers.

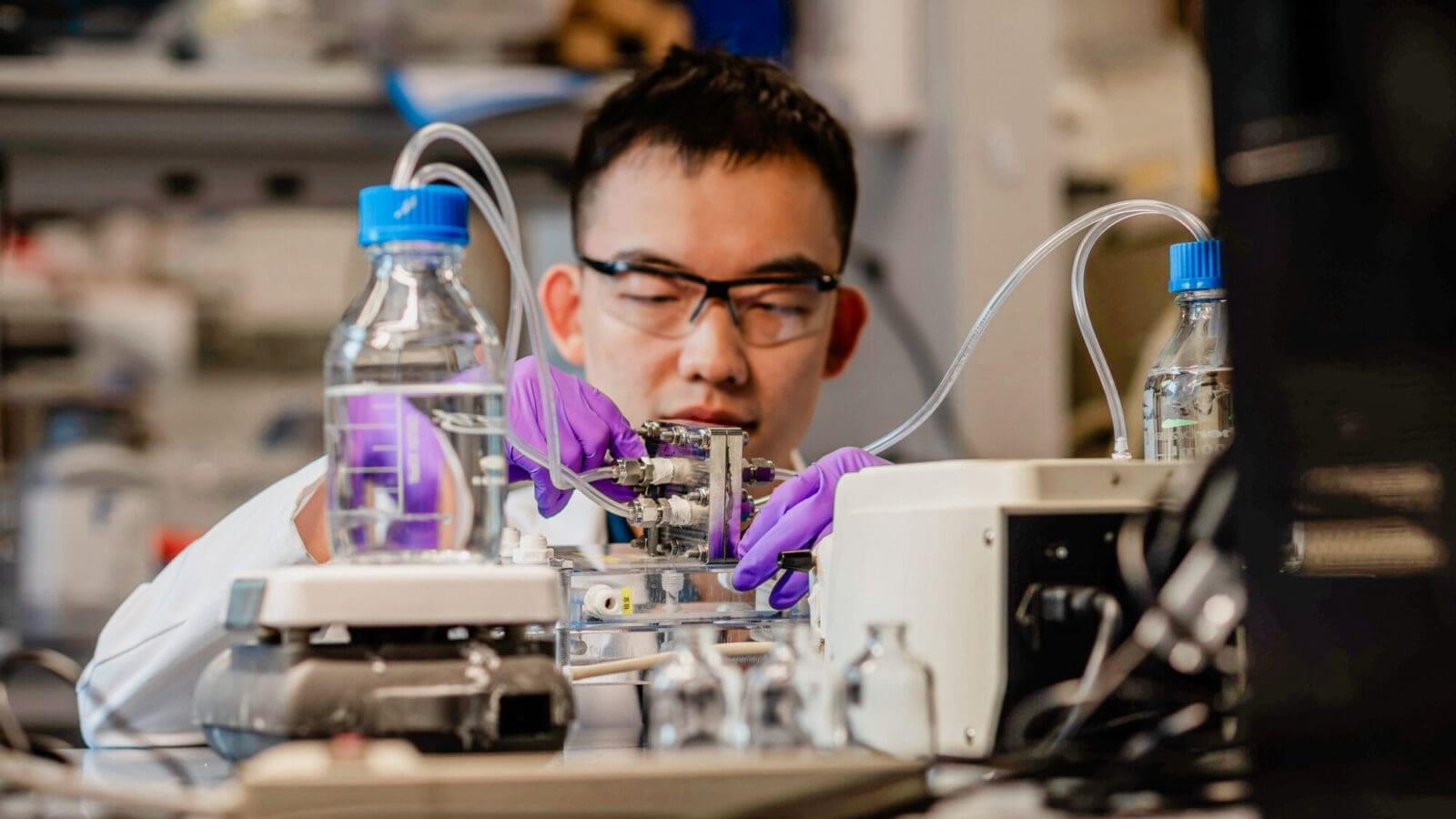

Spearheaded by Ci Lin, a Ph.D. student in HKU’s Department of Mechanical Engineering, the team’s work was published in ACS Energy Letters.

Green hydrogen is seen as a clean fuel that can help reduce carbon emissions across industries like steelmaking, chemical production, long-distance transportation, and seasonal energy storage. Proton exchange membrane (PEM) electrolyzers are preferred for their compact design and rapid response, but they operate in acidic conditions that are exceptionally demanding on the oxygen evolution reaction (OER) catalyst.