Upcoming missions to Mars have grabbed plenty of headlines in recent years, but before we set off for the Red Planet, a lot more research is needed – and that’s why NASA has a new plan for sending astronauts into orbit around the Moon.

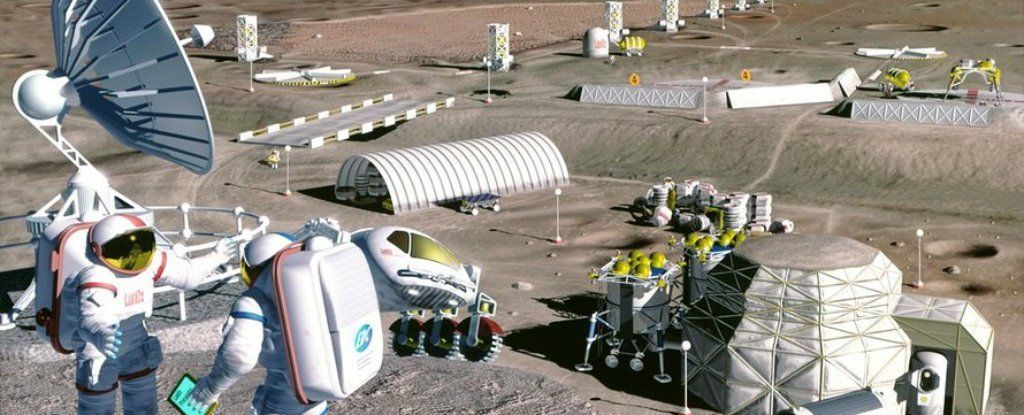

It’s been a while – we last set foot on the Moon in 1972. But NASA thinks the cislunar orbit (between the Moon and the Earth) is going to be an essential testing site and launching pad for reaching Mars in the 2030s.

As NASA’s Greg Williams explained this week at the Humans to Mars Summit in Washington DC, the Moon mission is on the slate for 2027 and could see a crew spending a year sailing above the lunar surface.