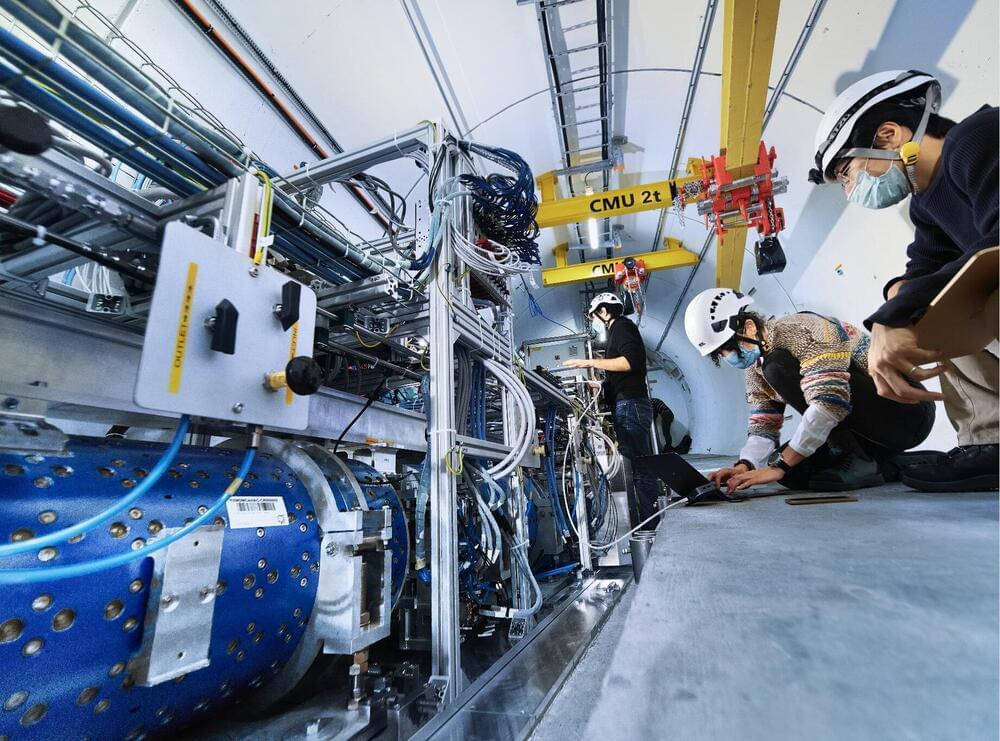

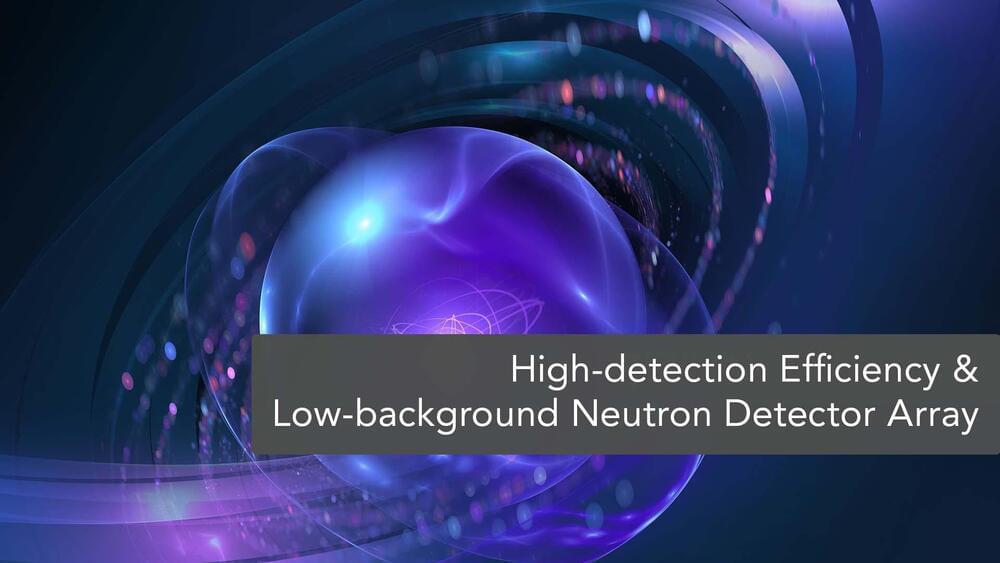

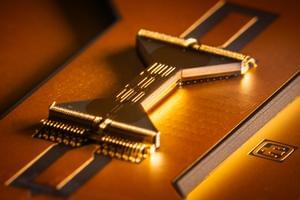

This study has successfully developed a high-efficiency neutron detector array with an exceptionally low background to measure the cross-section of the 13C(α, n)16O reaction at the China Jinping Underground Laboratory (CJPL). Comprising 24 3He proportional counters embedded in a polyethylene moderator, and shielded with 7% borated polyethylene layer, the neutron background at CJPL was as low as 4.5 counts/h, whereby 1.94 counts/h was attributed to the internal α radioactivity. Remarkably, the angular distribution of the 13C(α, n)16O reaction was proven to be a primary variable affecting the detection efficiency. The detection efficiency of the array for neutrons in the range of 0.1MeV to 4.5 MeV was determined using the 51V(p, n)51Cr reaction carried out with the 3 MV tandem accelerator at Sichuan University and Monte Carlo simulations. Future studies can be planned to focus on further improvement of the efficiency accuracy by measuring the angular distribution of 13C(α, n)16O reaction.

Gamow window is the range of energies which defines the optimal energy for reactions at a given temperature in stars. The nuclear cross-section of a nucleus is used to describe the probability that a nuclear reaction will occur. The 13C(α, n)16O reaction is the main neutron source for the slow neutron capture process (s-process) in asymptotic giant branch (AGB) stars, in which the 13C(α, n)16O reaction occurs at the Gamow window spanning from 150 to 230 keV. Hence, it is necessary to precisely measure the cross-section of 13C(α, n)16O reaction in this energy range. A low-background and high detection efficiency neutron detector is the essential equipment to carry out such measurements. This study developed a low-background neutron detector array that exhibited high detection efficiency to address the demands. With such development, advanced studies, including direct cross-section measurements of the key neutron source reactions in stars, can be conducted in the near future.

Low-background neutron detectors play a crucial role in facilitating research related to nuclear astrophysics, neutrino physics, and dark matter. By improving the efficiency and upgrading the technological capability of low background neutron detectors, this study indirectly contributes to the enhancement of scientific research. Additionally, fields involving material science and nuclear reactor technology would also benefit from the perfection of neutron detector technology. Taking into consideration the potential application and expansion of these findings, such innovative attempt aligns well with UNSDG9: Industry, Innovation & Infrastructure.