A research team led by Rice University neuroengineers has created wireless technology to remotely activate specific brain circuits in fruit flies in under one second.

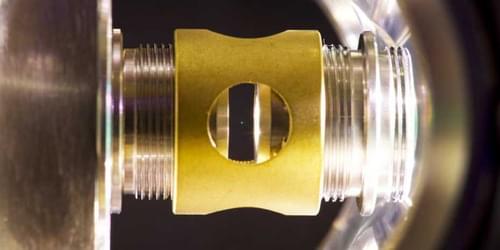

The team – an assemblage of experts in genetic engineering, nanotechnology, and electrical engineering – used magnetic signals to activate targeted neurons that controlled the body position of freely moving fruit flies in an enclosure.

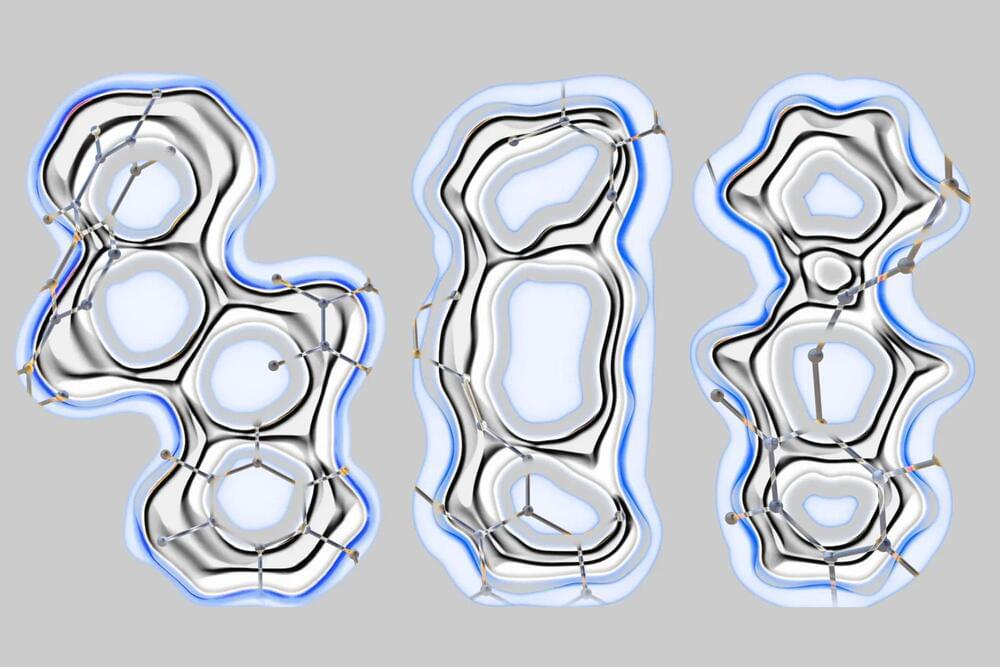

The researchers first created genetically modified flies bred to express a special heat-sensitive ion channel in neurons that cause flies to partially spread their wings, a common mating gesture. They then injected magnetic nanoparticles that could be heated with an applied magnetic field.