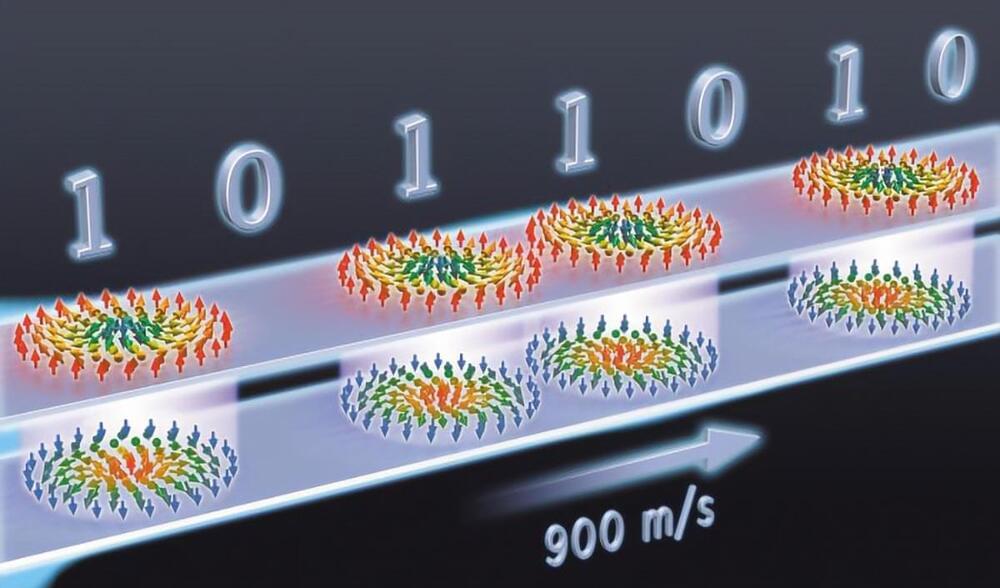

Scientists discovered that skyrmions, potential future bits for computer memory, can now move at speeds up to 900 m/s, a significant increase facilitated by the use of antiferromagnetic materials.

An international research team led by scientists from the CNRS[1] has discovered that the magnetic nanobubbles[2] known as skyrmions can be moved by electrical currents, attaining record speeds up to 900 m/s.

Anticipated as future bits in computer memory, these nanobubbles offer enhanced avenues for information processing in electronic devices. Their tiny size[3] provides great computing and information storage capacity, as well as low energy consumption.