Bill Gates has commissioned the construction of the Aqua superyacht, designed by Dutch studio Sinot. At 370ft long and 50ft wide, it is powered by two tanks of liquid hydrogen.

Category: futurism – Page 1,007

Zoltan Istvan on 2020 Presidential Campaign Against Trump

1-min C-SPAN video of why I’m running for President in 2020 against Donald Trump: https://www.facebook.com/ZoltanGIstvan/videos/208920663626290/ #UpgradingAmerica #Zoltan2020

Gov. Brown declares state of emergency

O.o!

From the office of the governor:

Salem, OR—Governor Kate Brown today declared a state of emergency in three Oregon counties due to severe flooding, increased snowmelt, landslides, and erosion. This declaration comes at the request of local legislators and is based on the recommendations of the Oregon Office of Emergency Management (OEM).

“Fast-moving, severe floods have required the evacuation of residences and shut down critical roads in northeastern Oregon. I am grateful for all of our first responders for their efforts to keep our families safe since the waters began rising,” Governor Brown said. “This emergency declaration ensures state resources, emergency response personnel, and equipment can be activated to complement critical local resources as this situation progresses.”

Too big to write but not too big for Graham

Recently, when we were writing our book Numericon, we came across what has now become one of our very favourite numbers: Graham’s number. One of the reasons we love it is that this number is big. Actually, that’s an understatement. Graham’s number is mind-bendingly huge.

This Exolung promises ‘unlimited’ air supply underwater

The Exolung is aiming for the sweet spot between scuba and snorkeling by using the power of kicking legs to pull a steady supply of air down from the surface.

CNET playlists: https://www.youtube.com/user/CNETTV/playlists

Download the new CNET app: https://cnet.app.link/GWuXq8ExzG

Like us on Facebook: https://www.facebook.com/cnet

Follow us on Twitter: https://www.twitter.com/cnet

Follow us on Instagram: http://bit.ly/2icCYYm

#Exolung #DiveTech

Sharks Are Evolving to Walk on Land

Four newly-discovered species of shark are capable of trotting around on land, using four fins as stubby legs.

They’re the most recently-evolved types of sharks known to science, according to CNET. And while they still live in the water, using their fins to crawl across coral reefs, they can briefly wriggle across dry land to migrate from one tide pool to another.

Mark L: The Mark L (Mark 50) is Tony Stark’s fiftieth Iron Man suit

Mark 50) is Tony Stark’s fiftieth Iron Man suit. It was built after the Mark XLVII. Mark XLVIII Hulkbuster Mark 2 whilst Mark XLIX is Rescue armor Mark 1 (confirmed by hot toys figure and other merchandise).

The Mark L has been used to battle Thanos and his allies. This armor is more advanced than any other previous armors, the entire armor is stored inside the detachable Arc reactor on Tony’s Chest, it possesses many capabilities and useful functions for Tony to use at his disposal.

Like the Marks XLV, XLVI, and XLVII, this armor has the F.R.I.D.A.Y OS built into it and possesses some of the most advanced technology and weapons compared to other armors Tony Stark has built.

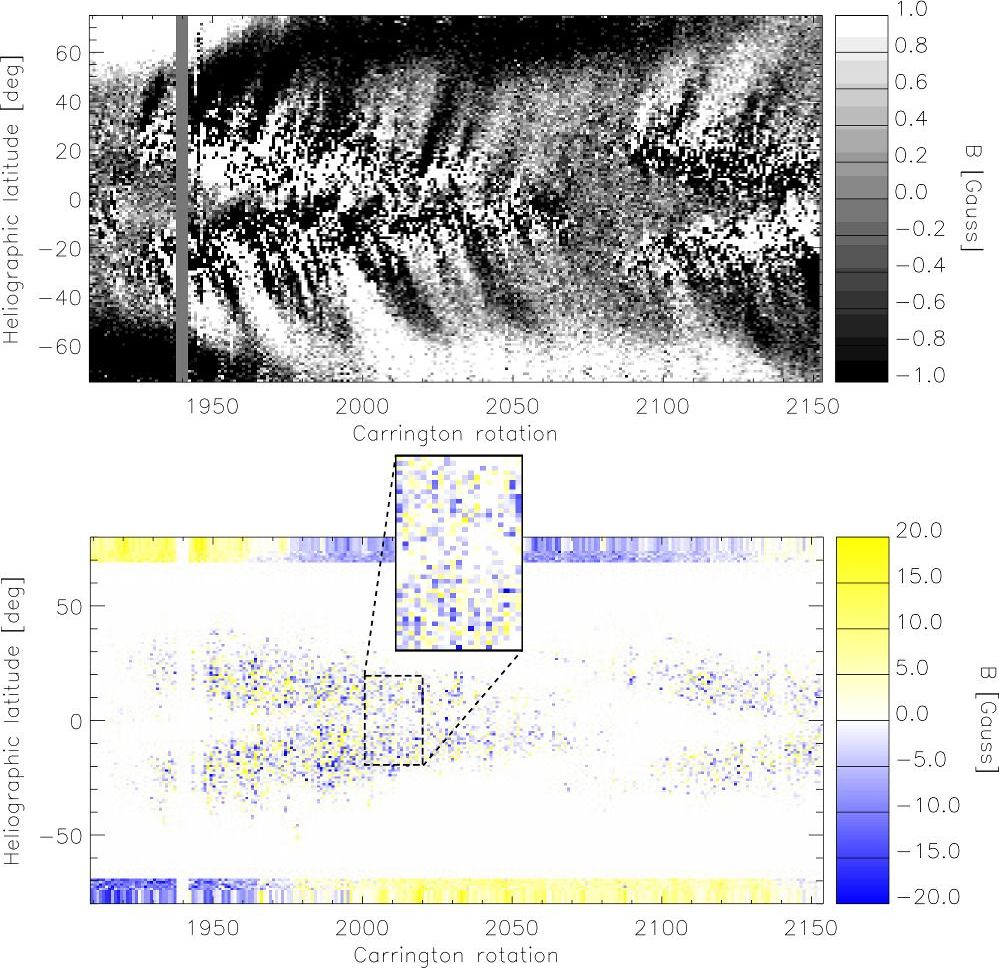

Polar Cap Magnetic Field Reversals During Solar Grand Minima: Could Pores Play a Role?

M. Švanda1,2, A. S. Brun3, Th. Roudier4, & L. Jouve4,3 1 Astronomical Institute, Academy of Sciences of the Czech Republic, Ondřejov, Czech Republic 2 Astronomical Institute, Charles University in Prague, Czech Republic 3 CEA Saclay, France 4 IRAP, Université de Toulouse, France.

The properties and origin of the solar cycle are still not well understood. They are nevertheless well described by a class of dynamo models that utilize the redistribution of magnetic flux due to systematic plasma flows, such as convection, differential rotation, supergranular diffusion, and meridional flows. These so called Babcock-Leighton-type (BL) dynamos1,2 have been successful in reproducing the features of solar cycle, including the reversal of the global magnetic field occurring every 11 years, and the propagation of solar activity toward the equator as the cycle progresses. BL dynamos rest entirely on the presence of tilted bipolar magnetic fields, where sunspots usually appear. Grand minima (such as Maunder minimum 1645–1715) are an issue for this class of models, since the needed source terms vanish. There is evidence, however, that solar cycles were present even during these periods3 when almost no spots were seen.

Observers in the Maunder minimum era mostly used smaller refractors, with an estimated angular resolution of 2” at best. Taking into account the seeing, we estimated the resolving power to be around 5”. Therefore they were probably unable to see the tiny spots, i.e., pores. Moreover, there is evidence of a recent secular decrease of solar activity4 when small sunspots become more frequent whereas large spots become rarer5.