In this episode, learn the art of prompt engineering to enhance your ChatGPT interactions. Discover tips for crafting effective prompts, interpreting results, and fine-tuning inputs. Ideal for both beginners and experienced users. Like, comment, and subscribe for more Singularity Syndicate episodes!

Category: engineering – Page 102

The Pursuit Of Better Camouflage Could Lead To An Invisibility Cloak

The invisibility cloak that Harry Potter wears in J. K. Rowling’s books is woven from the hair of a magical creature. But in the real world, the magic of invisibility is not dependent on fantasy, but rather on science and engineering.

Then there is quantum stealth technology that uses colouration patterns to hide objects in plain sight.

There are even camouflage technologies that make something as large as a tank appear to be local foliage, absorbing the characteristics of the organic and inorganic materials found on a battlefield.

As cool as Harry Potter’s cloak of invisibility appears to be, current and future materials science discoveries and technological advancements may have it beat.

Cultured meat firm resurrects woolly mammoth in lab-grown meatball

Vow, an Australian cultivated food company that creates meat in a laboratory setting from animal cells, says that it has used advanced molecular engineering to resurrect the woolly mammoth in meatball form, by combining original mammoth DNA with fragments of an African elephant’s DNA.

James Ryall, Vow’s chief science officer, said that the company first identified the mammoth myoglobin, a protein that is key to giving meat its color and taste, and then used publicly available data to identify the DNA sequence in mammoths.

Australian company Vow says it has used advanced molecular engineering to resurrect the woolly mammoth in meatball form.

The new Microsoft Teams is here with big performance improvements and UI changes

Microsoft Teams has been totally overhauled to run faster and have a more simplified interface.

Microsoft is overhauling its Teams app today to make it faster and easier to use. Microsoft Teams has been rebuilt from the ground up, with a new preview available today for businesses to try out this radical rework that has been years in the making.

“The new Teams is faster, simpler, and more flexible than ever before,” says Sumi Singh, CVP of engineering for Microsoft Teams, in an interview with The Verge. “We’ve made tremendous strides in performance and usability. The new Teams is 2x faster while using 50 percent fewer resources.”

The new Microsoft Teams isn’t all about looks and performance, though. Microsoft is also adding in some very useful improvements. If you’ve ever had issues switching between different Microsoft Teams accounts in your organization, the new client has an improved method to let you see all of your accounts and notifications in a single drop-down menu. You won’t have to log out of accounts and switch tenants to get access to different Teams instances.

If you’re used to meetings with raised hands even after someone has asked a question, Microsoft is now improving this experience by automatically lowering hands after the person has spoken. Whiteboard is also getting the ability to paste Loop components to make the canvas even more collaborative. AI-powered video filters are also coming to Microsoft Teams, with a number of animated frames and the ability to change your video’s hue in presentations.

Dr. Annie Kritcher, Ph.D. — National Ignition Facility — LLNL — Tapping The Power Of The Stars

Tapping The Power Of The Stars — Dr. Andrea Kritcher Ph.D., Lawrence Livermore National Laboratory, U.S. Department of Energy.

Dr. Andrea (Annie) Kritcher, Ph.D. is a nuclear engineer and physicist who works at the Lawrence Livermore National Laboratory (https://www.llnl.gov/). She is the design lead of the HYBRID-E capsule technology within Lawrence Livermore’s Inertial Confinement Fusion (ICF) program, and is a member of the ICF leadership team and lead designer for shot N210808, at their National Ignition Facility, a recent experiment that heralded a significant step towards a fusion break-even target. She was elected Fellow of the American Physical Society in 2022.

Dr. Kritcher was first employed at Lawrence Livermore as a summer intern in 2004, as an LLNL Lawrence Scholar during her time at UC Berkeley, where she earned a master’s degree and doctorate in nuclear engineering, and as a Lawrence postdoctoral fellow in 2009 following completion of her Ph.D. During her postdoctoral appointment she explored using X-rays to measure the properties of warm and hot dense matter (plasma), and measuring how nuclei interact with dense plasma.

In 2012, Dr. Kritcher became a member of scientific staff and now serves as team lead for integrated implosion modeling and is a group leader within the design physics division at LLNL.

Lawrence Livermore National Laboratory (LLNL) is a federally funded research and development center in Livermore, California, United States. Originally established in 1952, the laboratory now is sponsored by the United States Department of Energy. Its principal responsibility is ensuring the safety, security and reliability of the nation’s nuclear weapons through the application of advanced science, engineering, and technology. The laboratory also applies its special expertise and multidisciplinary capabilities towards preventing the proliferation and use of weapons of mass destruction, bolstering homeland security, and solving other nationally important problems, including energy and environmental needs, scientific research and outreach, and economic competitiveness.

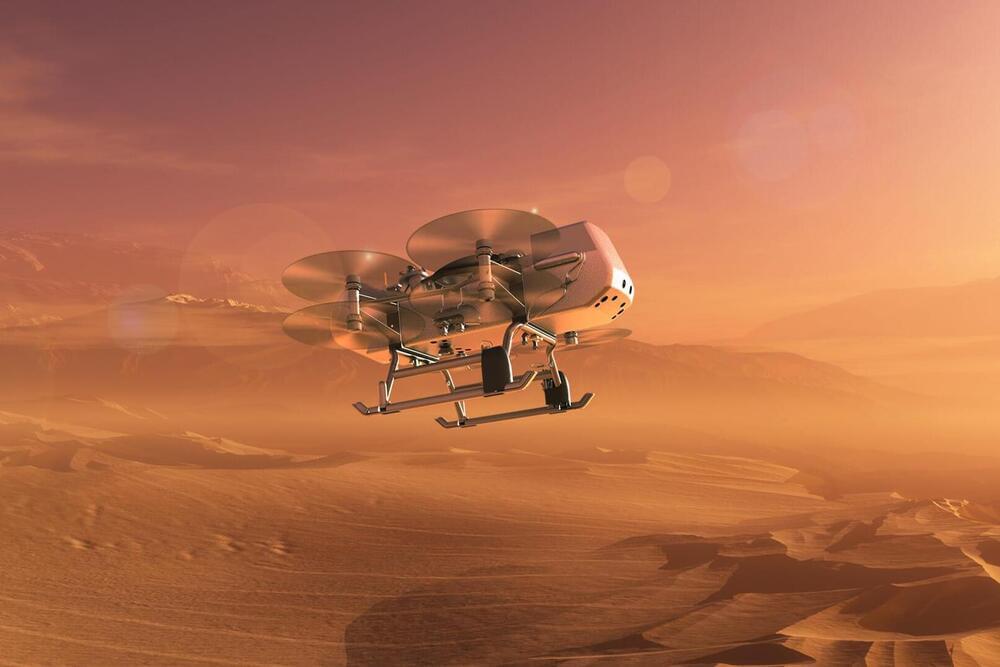

Civil Space

Johns Hopkins APL’s Civil Space Mission Area makes critical contributions to NASA and international missions to meet the challenges of space science, engineering, and exploration.

Since the dawn of the Space Age, APL has pushed the frontiers of space science, engineering and exploration. We captured the first picture of Earth from space, invented navigation by satellite, dispatched spacecraft across the solar system from our Sun to Pluto and beyond, and successfully conducted the world’s first full-scale planetary defense test mission.

We continue to shape the future by providing our nation with innovative and low-cost solutions to its space challenges. Our work includes conducting research and space exploration; development and application of space science, engineering, and technology; and production of one-of-a-kind spacecraft, instruments, and subsystems.

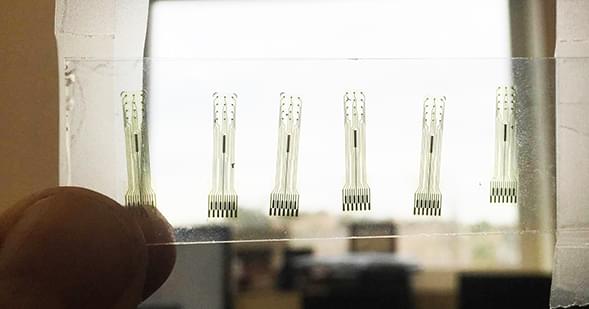

Big improvements to brain-computer interface

When people suffer spinal cord injuries and lose mobility in their limbs, it’s a neural signal processing problem. The brain can still send clear electrical impulses and the limbs can still receive them, but the signal gets lost in the damaged spinal cord.

The Center for Sensorimotor Neural Engineering (CSNE)—a collaboration of San Diego State University with the University of Washington (UW) and the Massachusetts Institute of Technology (MIT)—is working on an implantable brain chip that can record neural electrical signals and transmit them to receivers in the limb, bypassing the damage and restoring movement. Recently, these researchers described in a study published in the journal Nature Scientific Reports a critical improvement to the technology that could make it more durable, last longer in the body and transmit clearer, stronger signals.

The technology, known as a brain-computer interface, records and transmits signals through electrodes, which are tiny pieces of material that read signals from brain chemicals known as neurotransmitters. By recording brain signals at the moment a person intends to make some movement, the interface learns the relevant electrical signal pattern and can transmit that pattern to the limb’s nerves, or even to a prosthetic limb, restoring mobility and motor function.

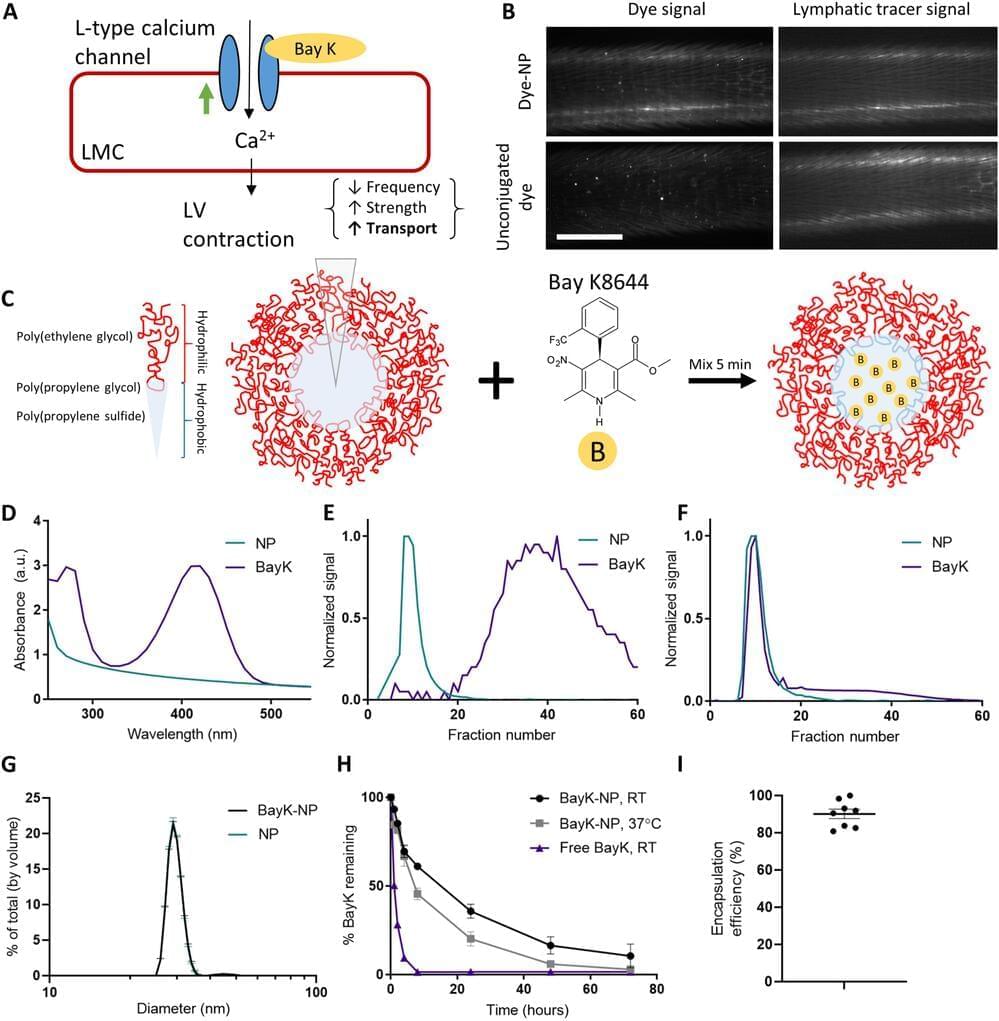

Nanotechnology could be used to treat lymphedema

The human body is made up of thousands of tiny lymphatic vessels that ferry white blood cells and proteins around the body, like a superhighway of the immune system. It’s remarkably efficient, but if damaged from injury or cancer treatment, the whole system starts to fail. The resulting fluid retention and swelling, called lymphedema, isn’t just uncomfortable—it’s also irreversible.

When lymphatic vessels fail, typically their ability to pump out the fluid is compromised. Georgia Institute of Technology researchers have developed a new treatment using nanoparticles that can repair lymphatic vessel pumping. Traditionally, researchers in the field have tried to regrow lymphatic vessels, but repairing the pumping action is a unique approach.

“With many patients, the challenge is that the lymphatic vessels that still exist in the patient aren’t working. So it’s not that you need to grow new vessels that you can think of as tubes, it’s that you need to get the tubes to work, which for lymphatic vessels means to pump,” said Brandon Dixon, a professor in the George W. Woodruff School of Mechanical Engineering. “That’s where our approach is really different. It delivers a drug to help lymphatic vessels pump using a nanoparticle that can drain into the diseased vessels themselves.”

Unprecedented Breakthrough in Manipulating “Quantum Light”

For the first time, scientists at the University of Sydney.

The University of Sydney is a public research university located in Sydney, New South Wales, Australia. Founded in 1,850, it is the oldest university in Australia and is consistently ranked among the top universities in the world. The University of Sydney has a strong focus on research and offers a wide range of undergraduate and postgraduate programs across a variety of disciplines, including arts, business, engineering, law, medicine, and science.

Nvidia builds quantum-classical computing system with Israel’s Quantum Machines

US gaming and computer graphics giant Nvidia has joined forces with an Israeli startup to roll out a new hardware system to connect the quantum computer with classical computers.

The new system, Nvidia DGX Quantum, built together with Israel’s Quantum Machines, a developer of a standard universal language for quantum computers, is expected to be first deployed at Israel’s quantum computing research center at the end of this year.

The quantum computing R&D center funded by the Israel Innovation Authority at an investment of NIS 100 million ($27 million), which is headed by Quantum Machines, was established to help Israel build a quantum computer and advance research in the field that would lead to future developments in economics, technology, security, engineering, and science.