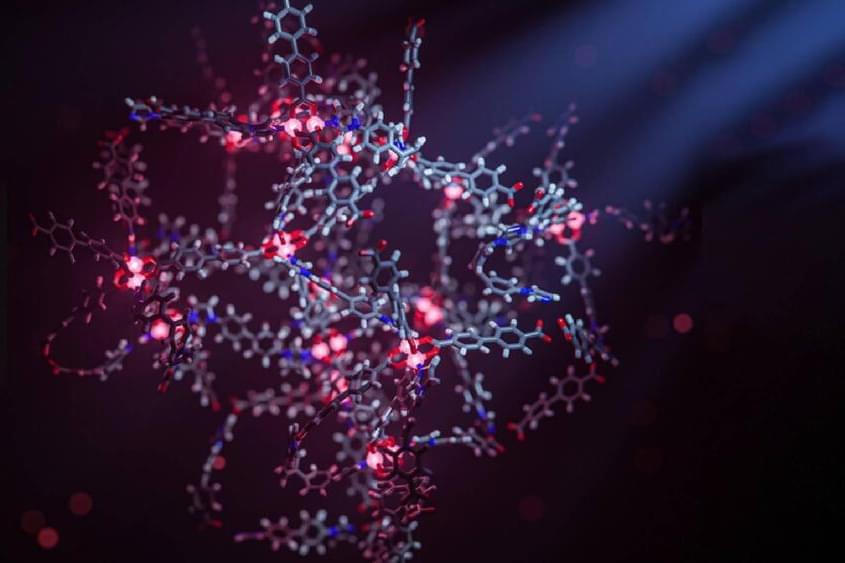

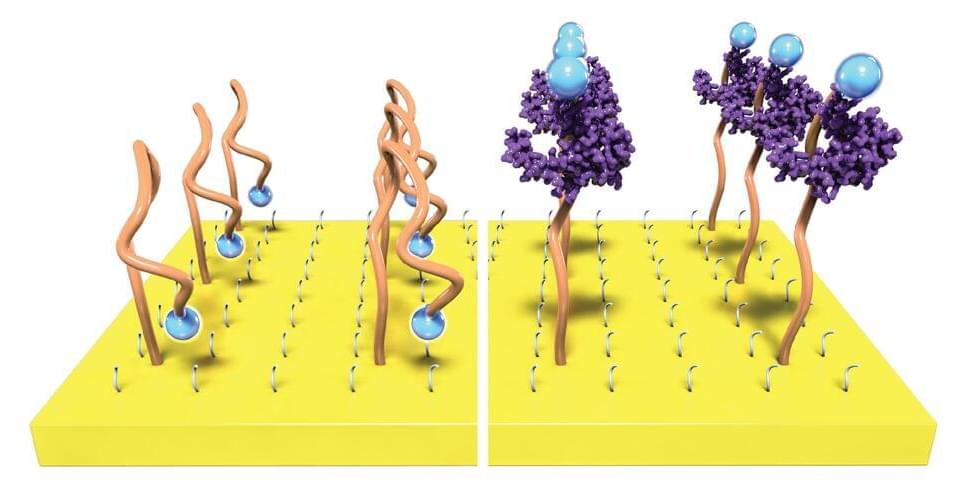

In an advance they consider a breakthrough in computational chemistry research, University of Wisconsin–Madison chemical engineers have developed model of how catalytic reactions work at the atomic scale. This understanding could allow engineers and chemists to develop more efficient catalysts and tune industrial processes—potentially with enormous energy savings, given that 90% of the products we encounter in our lives are produced, at least partially, via catalysis.

Catalyst materials accelerate chemical reactions without undergoing changes themselves. They are critical for refining petroleum products and for manufacturing pharmaceuticals, plastics, food additives, fertilizers, green fuels, industrial chemicals and much more.

Scientists and engineers have spent decades fine-tuning catalytic reactions—yet because it’s currently impossible to directly observe those reactions at the extreme temperatures and pressures often involved in industrial-scale catalysis, they haven’t known exactly what is taking place on the nano and atomic scales. This new research helps unravel that mystery with potentially major ramifications for industry.