The 19 3D-printable parts that make up the mask are visible on the Maker Mask website along with details on materials needed, download instructions, videos, the ability to donate to the cause and more. The cost of each finished mask, printed in about three hours, is estimated to be between $2 and $3.

A technology veteran and a 3D-printing “savant” have teamed with other members of industry, health care and government to launch Maker Mask, a Seattle nonprofit creating medically endorsed, reusable protective masks using everyday 3D printers.

Jonathan Roberts, founder and partner at the Bellevue, Wash.-based venture capital firm Ignition Partners, is also a co-founder of RPrime, a nonprofit that is helping to fund the mask-making initiative. The former Microsoft executive said the goal is to address critical supply shortages and support “the real heroes on the front lines” of the COVID-19 pandemic.

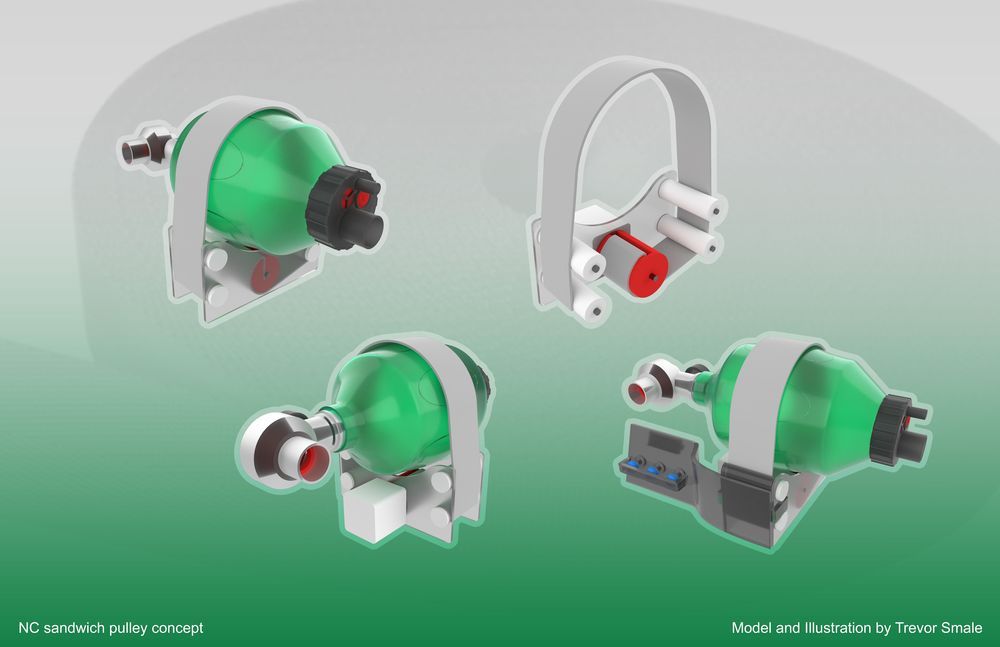

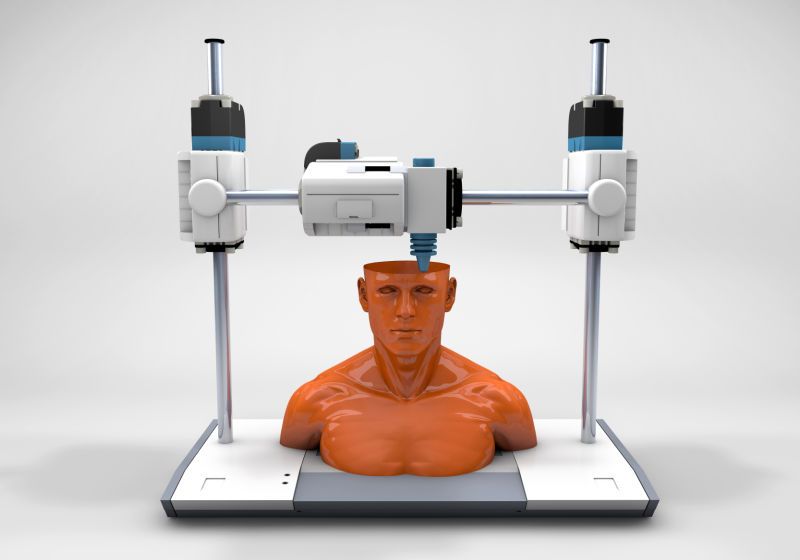

The respirator-style mask with a replaceable HEPA filter and other commonly available parts, was developed by Rory Larson, a rapid prototyping expert with 10 years experience in engineering, CAD, 3D printing, CNC and small batch production manufacturing. It took just a week for the group, working with Larson’s design, to get a small production facility up and running out of Epiphany Parish in Seattle.