Solar cell manufacturing just became easier, more efficient, and less costly. A team of researchers at DOE’s Lawrence Berkeley National Laboratory (Berkeley Lab), in collaboration with UC Berkeley, has discovered a unique material that can be used as a simpler approach to solar cell manufacturing, the team reported.

This material is a crystalline solar material with a built-in electric field — also known as “ferroelectricity” — that was reported earlier this year in the journal Science Advances.

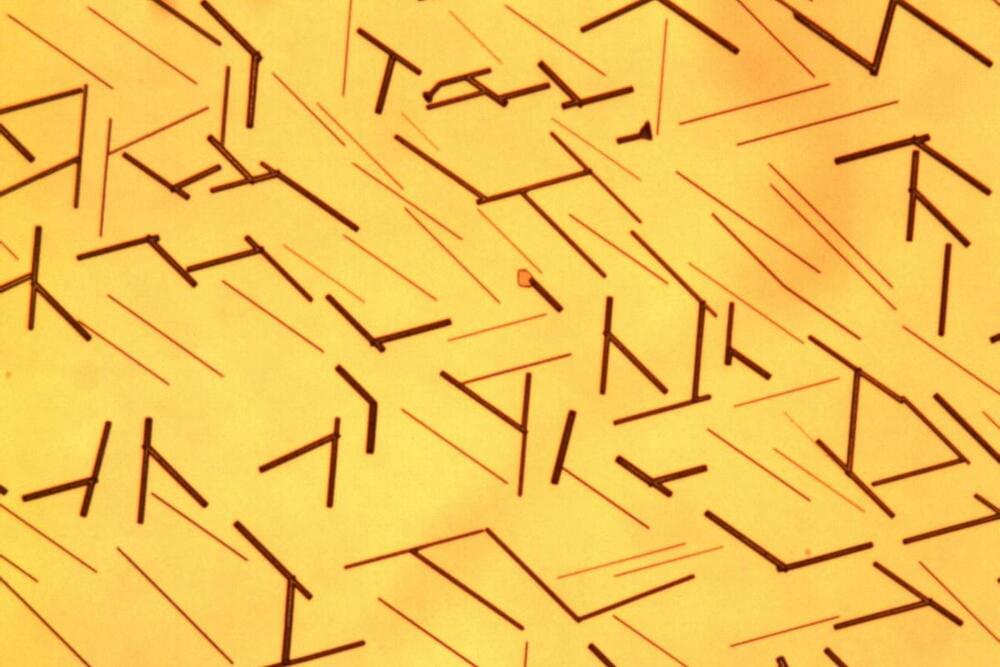

Light microscopy image of nanowires, 100 to 1,000 nanometers in diameter, grown from cesium germanium tribromide (CGB) on a mica substrate. The CGB nanowires are samples of a new lead-free halide perovskite solar material that is also ferroelectric. (Credit: Peidong Yang and Ye Zhang/Berkeley Lab)

Solar panels, also known as photovoltaics, rely on semiconductor devices, or solar cells, to convert energy from the sun into electricity.

To generate electricity, solar cells need an electric field to separate positive charges from negative charges. To get this field, manufacturers typically dope the solar cell with chemicals so that one layer of the device bears a positive charge and another layer a negative charge. This multilayered design ensures that electrons flow from the negative side of a device to the positive side – a key factor in device stability and performance. But chemical doping and layered synthesis also add extra costly steps in solar cell manufacturing.

Comments are closed.